Prepare

Notes:

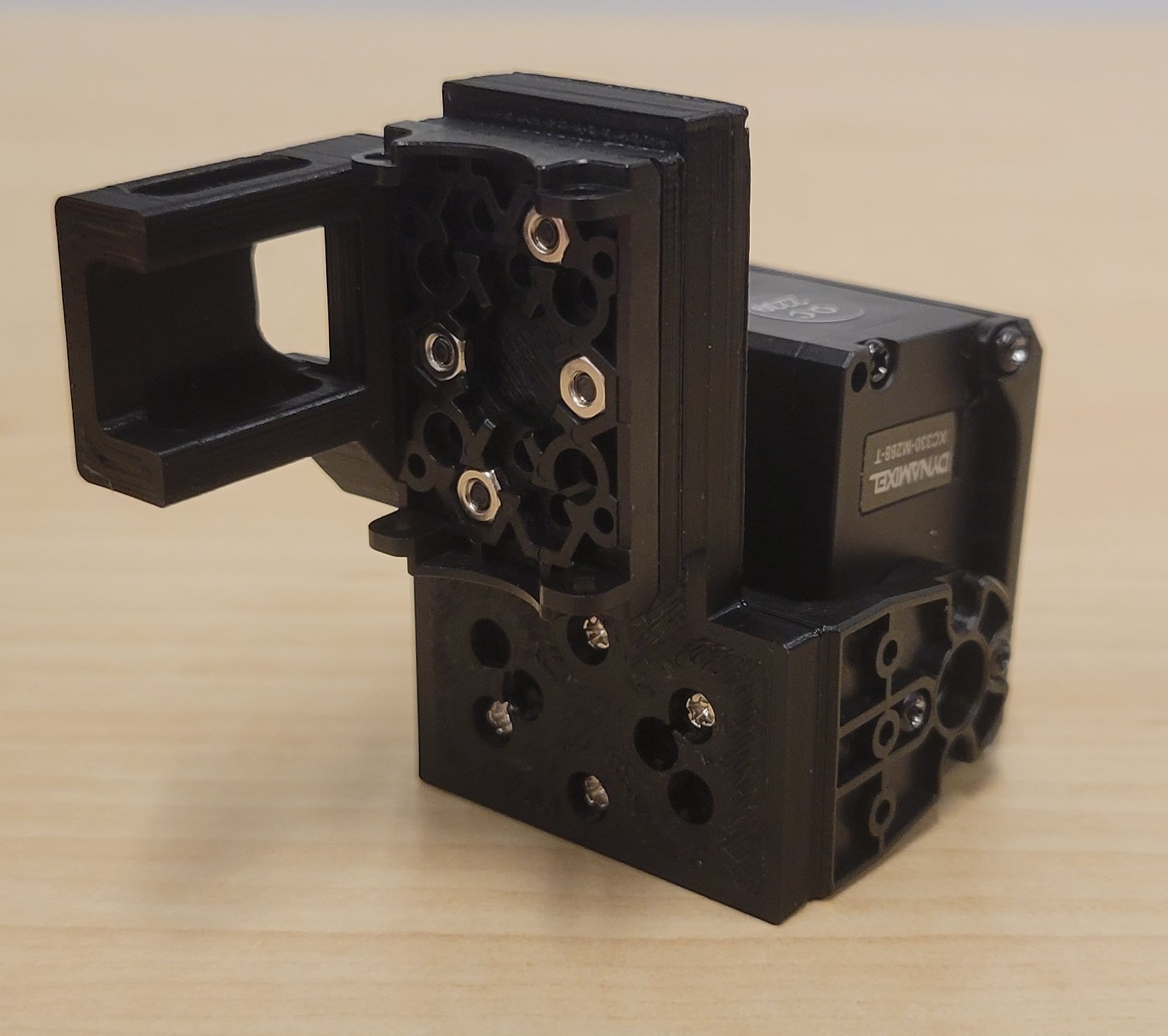

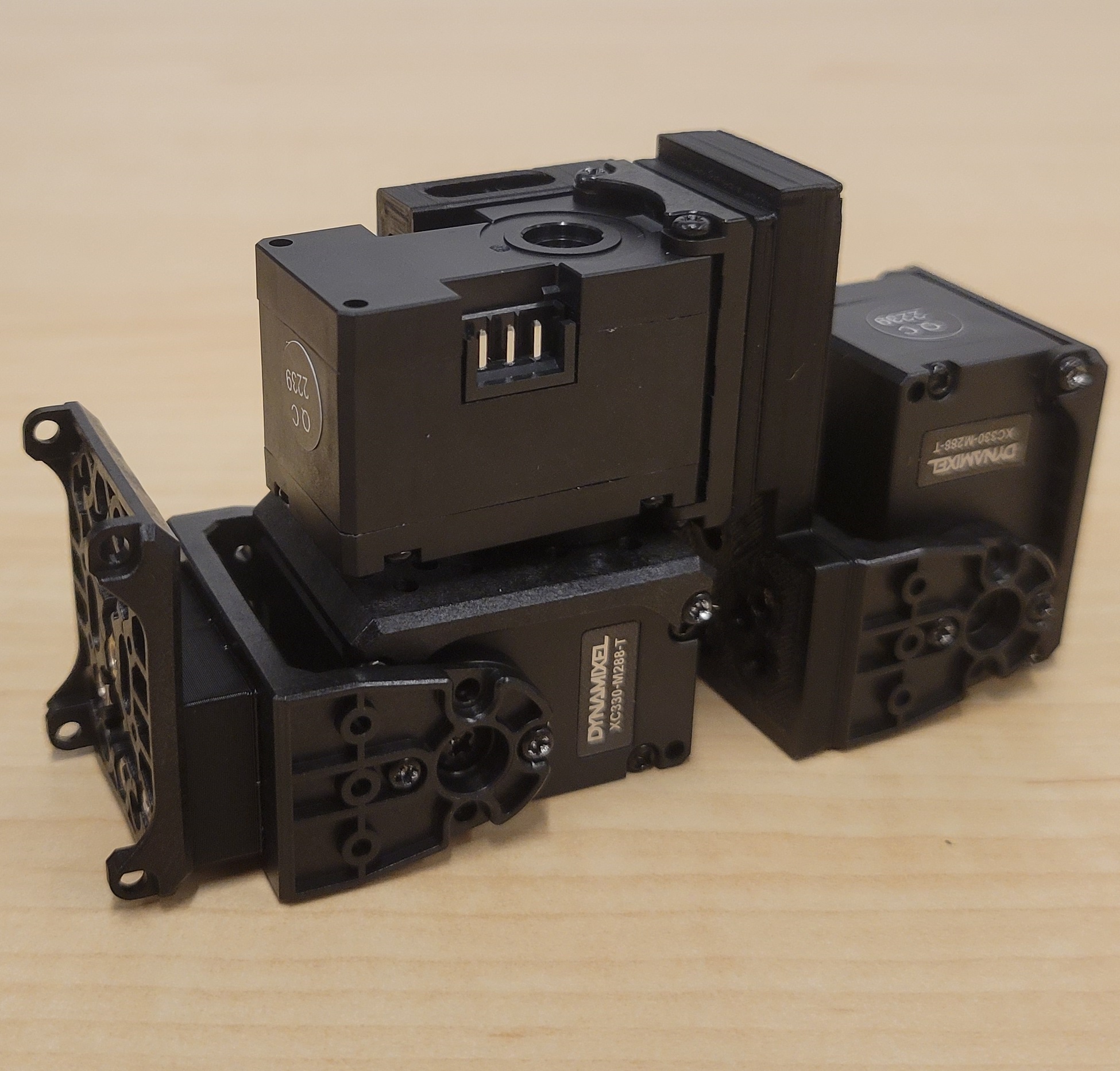

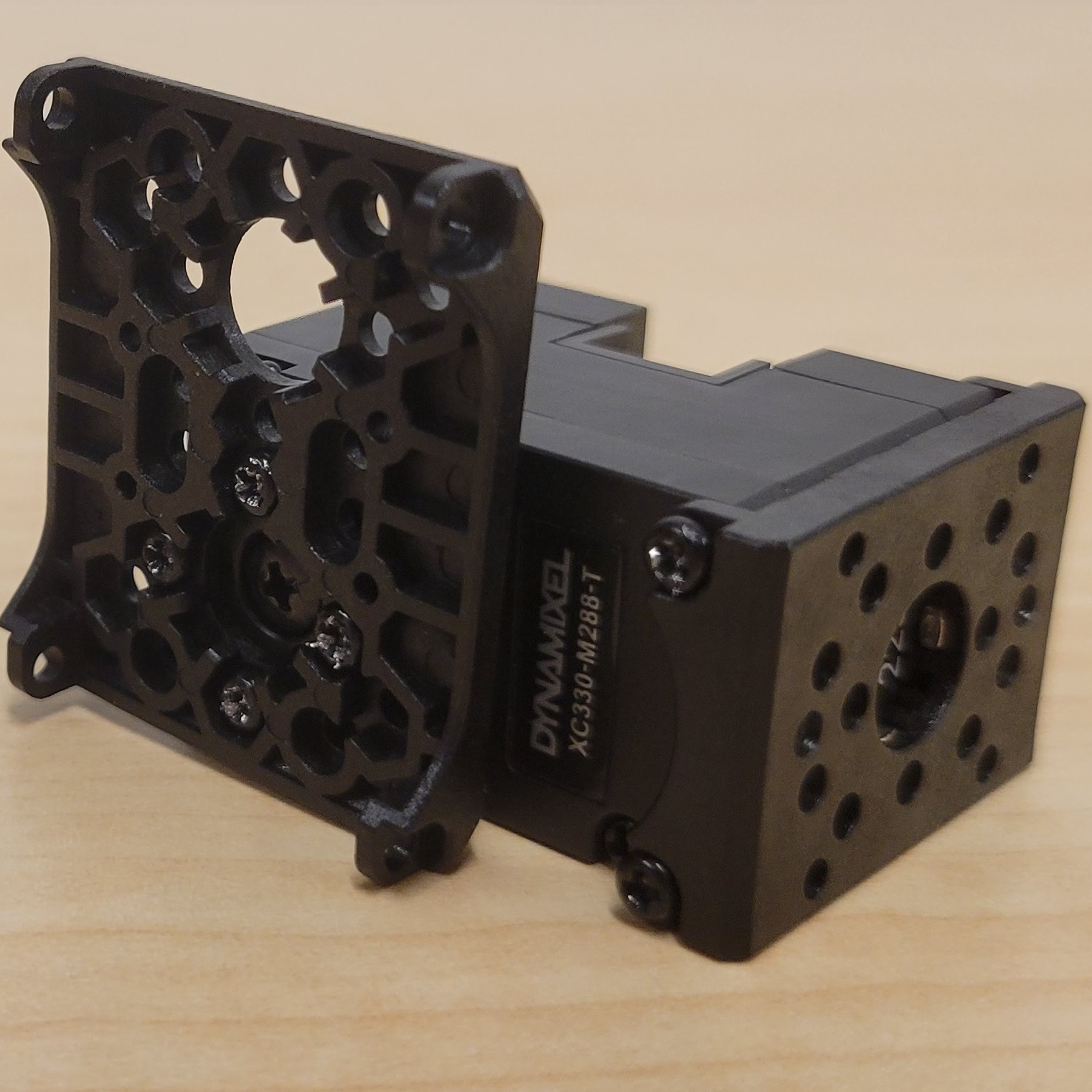

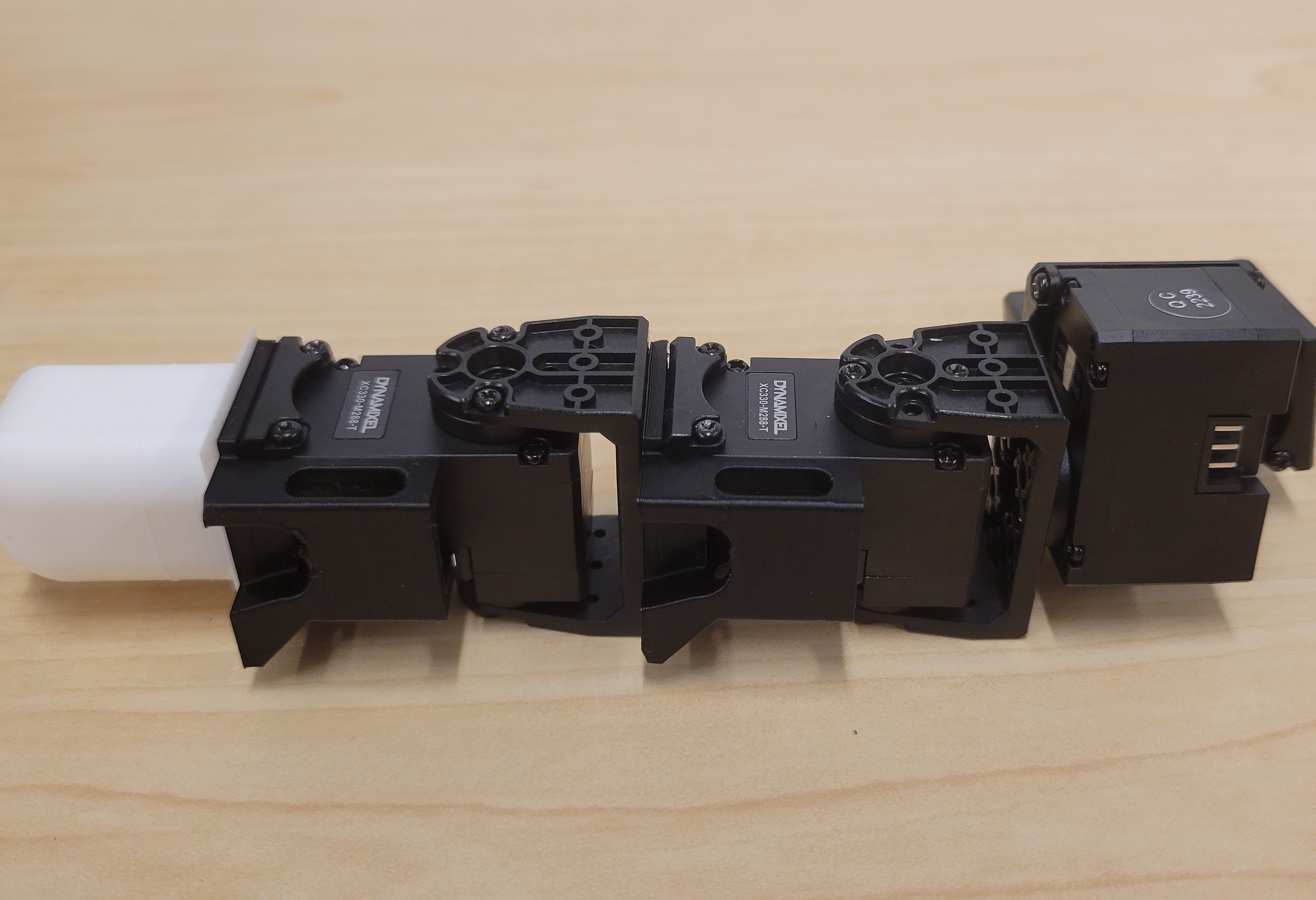

1) This is the Home pose (180 deg.) of the dynamixel, see dots on the horn. They are usually shipped this way. Make sure the parts are attached so that the motors going to the home pose

makes the hand go to the home position as in the CAD above. 2) Pay attention to the types of screws. "TAP" screws are phillips head, have a serrated edge, and come with the Dynamixel brackets. The other ones are regular hex head. M2/M3 stands for the diameter of the screw and the second number is the length.